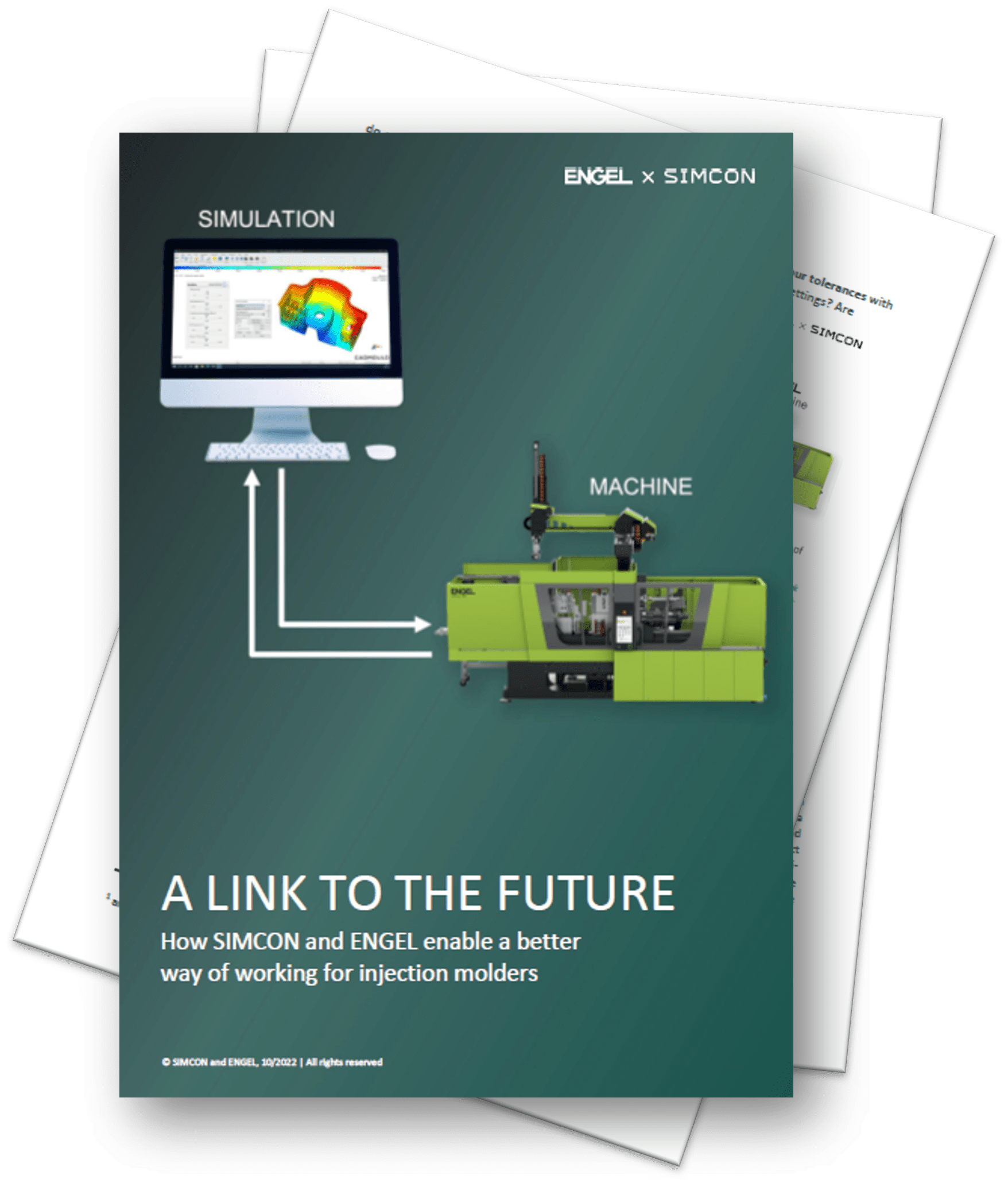

Link to the future: How ENGEL & SIMCON enable a better way of working

Bi-directional communication between the simulation and the machine makes it easier for engineering and the shop floor to collaborate effectively.

2020 has been a challenging environment for many companies, on many fronts. Due to the pandemic, the macroeconomic climate has been challenging. Lockdowns and their drastic impacts on supply chains have shone a harsh spotlight on the value of agility. In a rapidly shifting environment, with entire supply chains having to adjust to wild shifts in demand, flexible adaptation is crucial. To achieve this, efficient ways of working and a fast time to market are real competitive advantages – but only, if quality can be boosted simultaneously.

TE Connectivity recognizes potential of seamless digital chains

Digital simulation and measurement tools are a prime way for companies to accelerate, while simultaneously boosting quality in engineering. The benefits of well-integrated digital processes have been clear for some time – and if anything, Covid-19 has made them even more clear.

One of the key things to get right in digitalization, is to make it end-to-end. Since different steps of the engineering process often use different software solutions, it is crucial that they work together seamlessly. In this vein, our customer TE Connectivity realized that there was considerable potential from better integrating their digital plastic part development process (which they did with SIMCON’s simulation solution CADMOULD and optimization solution VARIMOS) with quality control (which they performed using powerful CT scan methods and the software suite VGMETROLOGY, by Volume Graphics). TE Connectivity (TE) realized the potential of combining the power of this software with SIMCON’s VARIMOS optimization technology – so that parts can be optimized for exactly the same quality measures that are later used to assess part quality. The question then became, how to make it happen.

Challenges in digital integration

While many players know they should push digitalization, and many have developed good ideas on what they want to do, it is not easy to realize such cross-connections with purely internal resources. The job market for good software engineers is wiped clean. Established producing companies compete for the best talent with top international companies and startups, who offer top salaries and highly stimulating work environments in digital hubs like the Bay Area, Seattle, Dublin or in Germany, Berlin. Furthermore, classic corporate cultural environments often face challenges with the kinds of shifts that are necessary to attract, excite and retain exceptional digital talent. All of this makes it challenging to rapidly push digitalization forward, with organically built internal teams, even if you know what it is that you want to do – particularly in decentralized markets like Germany.

Pragmatic and rapid progress through innovation networks

TE Connectivity took a pragmatic and efficient approach to this challenge. In this example, they used strategic partnerships with their software partners Volume Graphics and SIMCON, and orchestrated them to quickly develop the kinds of integrated solutions they needed.

The approach of working in this networked way with external partners was that the solution was developed rapidly, with minimal use of internal resources, in an agile way. The development was beneficial for all parties – TE got the solution they needed, and Volume Graphics and SIMCON were able to develop a partnership and realize a great product innovation.

Network innovation as a strength of Germany as a business location

The German economy, despite its decentalized structure, offers ample opportunity to realize such networked collaboration models. We wholeheartedly recommend this approach to practitioners who would like to push digitalization quickly and efficiently, without having to go through the pain of recruiting and managing the kinds of talent needed to make progress at pace.

SIMCON would like to congratulate TE Connectivity and Volume Graphics on their contagious innovative and entrepreneurial spirit, and we are looking forward to deepening our relationship even further in the future.

You can read more about TE’s journey, the networked collaboration that ensued, and the solution developed, in TE Connectivity’s press release, on their website at https://www.te.com/usa-en/industries/automotive/insights/networked-innovation.html?_lrsc=c8663497-63bc-45c4-9ea7-655bc7cc09ea

TE Connectivity, TE, and TE connectivity (logo) are trademarks licensed by the TE Connectivity Ltd. family of companies. SIMCON, VARIMOS and CADMOULD are trademarks of the SIMCON Worldwide family of companies. Any other logos, company, product or service names mentioned in this article are used for identification purposes only and may be trademarks of their respective owners.

Bi-directional communication between the simulation and the machine makes it easier for engineering and the shop floor to collaborate effectively.

Paperless parameter transfer from simulation to the injection molding machine is crucial, if injection molders want better results.

Fast series production with significantly reduced warpage. This was the result of PLASTON and GOLLMER Formen working together to refine the mold...