Vorausschauend

Sagen Sie voraus, was im Inneren der Form passieren wird, bevor Sie die Form bauen. Erkennen Sie Probleme, bevor sie auftreten! Verstehen Sie, warum Probleme auftreten.

Erzielen Sie schneller qualitativ hochwertigere Ergebnisse beim Design von Formteil, Werkzeug und Parametern, im Kunststoff-Spritzguss.

Kunststoffspritzgießen ist unsere Leidenschaft. Seit mehr als 30 Jahren helfen wir unseren Kunden bei ihren schwierigsten technischen Herausforderungen.

Als Ausgründung aus dem IKV der RWTH Aachen schlägt unser Herz für die Werte des deutschen Ingenieurshandwerks.

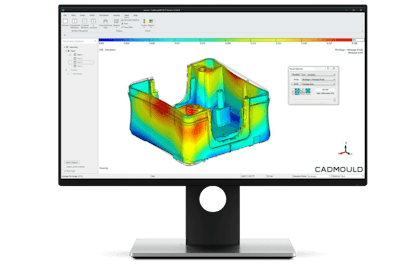

Wir haben CADMOULD und VARIMOS entwickelt, um die schwierigsten Fragen unserer Kunden beantworten zu können.

Virtualisieren Sie Ihr Engineering und erzielen Sie bessere Ergebnisse!

Mit unseren leistungsstarken Virtualisierungstools können Sie Fehler vorhersehen und vermeiden und so schneller bessere Ergebnisse erzielen. Das Ergebnis sind geringere Kosten für Korrekturen, kürzere Markteinführungszeiten und eine bessere Serienproduktion (bessere Qualität, kürzere Zykluszeiten, weniger Materialabfall usw.).

Sagen Sie voraus, was im Inneren der Form passieren wird, bevor Sie die Form bauen. Erkennen Sie Probleme, bevor sie auftreten! Verstehen Sie, warum Probleme auftreten.

Testen Sie verschiedene Lösungen, bevor Sie die Form bauen. Prüfen Sie, was funktioniert. Virtualisieren Sie Ihre Formkorrekturen! Machen Sie es gleich beim ersten Mal richtig!

Überlegene Lösungen finden. Verbessern Sie die Zykluszeiten. Kosten reduzieren. Reduzieren Sie den Material- und Energieeinsatz. Verbessern Sie die Nachhaltigkeit.

Bessere Ergebnisse schneller erzielen als mit Versuch und Irrtum. Weniger Zeit für Formkorrekturen. Kürzere Zeit bis zur Marktreife! Testen Sie viele Lösungen auf einmal und parallel und lernen Sie schneller.

Sprechen Sie mit einem unserer Experten und wir schätzen gemeinsam das ökonomische Potenzial für Sie und Ihr Unternehmen. Mit unserer Business-Case-Modellierung können wir schnell gemeinsam abschätzen, wie und ab wann sich die Einführung von Simulations- und Optimierungssoftware für Ihr Unternehmen amortisiert.

Ein Tipp: Digitale Transformation ist mehr als "nur" die Installation einer Software. Es geht um ein deutliches Upgrade Ihrer täglichen Arbeitsweise! Dabei geht es um Teamarbeit und bessere Kommunikation ebenso wie um Software.

Lesen Sie unser Whitepaper (gemeinsam mit Volume Graphics verfasst) über die Modernisierung Ihrer Arbeitsweise beim digitalen Spritzgießdesign!

Vermeiden Sie typische Fallstricke und verbessern Sie Ihre Arbeitsweise noch heute!

SIMCON und HellermannTyton:

Dr. Bastiaan Oud & Dr. Paul Filz (SIMCON) mit Johannes Mann & Kai Winter (Volume Graphics):