3 min read

Injection Molding Simulation in China: New Partnership SIMCON & ZIMMY

Shanghai, People’s Republic of China, March 18, 2021 Simulation and optimization solutions now available at ZIMMY, China Digital engineering...

Koorean CAD/CAM specialist INCOS INC is now distributing SIMCON’s plastic injection molding simulation and optimization software CADMOULD and VARIMOS.

Renowned plastic injection molding simulation specialist SIMCON announced today that it has reached a distribution agreement with innovative Industrial IoT and Engineering Software specialist INCOS INC. INCOS will engage in regional marketing and sales, and provide local technical support for CADMOULD, SIMCON’s cutting-edge injection molding simulation software, as well as the unique automatic optimization solution VARIMOS. INCOS will therefore join SIMCON’s reseller team for the Korean Market.

“We are deeply impressed with the development and growing sophistication of the Korean plastics injection molding market. There is so much potential here.”, explains Sebastian Sutter, International Business Development Manager at SIMCON. “Our customers save a lot of time and money by using our software solutions. They shorten their development cycles, reduce costly correction loops, and get better first-time-right results. This gives them better quality and faster time to market. We are excited to work with INCOS to make the best German engineering technology available to our customers in Korea.”

INCOS CEO Mr. CG (Cheolgyu) Hwang is particularly excited about offering SIMCON’s world-leading optimization technology VARIMOS to customers. “SIMCON’s solutions are a great addition to our CAD/CAM portfolio. We find that some of our CAD/CAM customers have already begun to explore injection molding simulation. And that is a real advantage, because you are testing alternatives virtually, which is faster and cheaper than trying it in real life. But they still use it in an inefficient way. They are generating and simulating different alternatives one by one, to compare them and see what works. Why not automate that step and use artificial intelligence to help you do that testing and exploration, and find a better solution, automatically? That is where VARIMOS comes in. There’s nothing else quite like it in the market.”

“In fact, this is why several of the leading German car manufacturers and their suppliers use it in their part and mold design process,” adds SIMCON CEO Dr. Paul Filz. “Instead of wasting precious engineer time on trying variants one by one, let the artificial intelligence in VARIMOS to the busywork, and focus the engineers on discussing results and options, to make decisions and resolve tradeoffs between competing goals. Because that is the part that only humans can do.”

The basis for these optimization tools is SIMCON’s simulation software CADMOULD, which simulates comprehensive injection results. Engineers use this to anticipate and fix filling issues, as well as shrinkage and warpage, to improve injection molded parts, molds and process parameters.

Thanks to CADMOULD’s modular design, there is a range of packages for different needs. Customers can buy the exact functionality that they require for their projects. No need to pay for features you do not need.

Because CADMOULD has the world’s leading 3D-F injection molding simulation algorithm, it is incredibly fast and precise at the same time. Its unrivalled speed is the foundation for being able to run optimization with VARIMOS, because optimizing requires running many simulations, to explore the options. Thanks to CADMOULD’s multi-core parallelization technology, this is incredibly fast and efficient. CADMOULD also supports 3D Volumetric meshing, in case you are working with particularly thick-walled parts like optical lenses. “We invite you to see the speed for yourself in a demo. For most of our customers, there is no need for expensive hardware upgrades. You can get going right away!”, says Mr. CG Hwang.

INCOS also offers support and services for customers who may not yet have staff trained to use simulation software. Mr. CG Hwang explains: “CADMOULD and VARIMOS are really simple to use, and it’s easy to learn and get started. But in case you want to get started quickly and test the benefits before investing into the software and training, we also offer simulation and optimization as a service.

Talk to us about what you would like to achieve, and we will help you make it happen. That way you can see what you can achieve with our tools. We’re also happy to make our services redundant by training your team and helping you to get started! We offer extensive user training for SIMCON software, and there is an online academy for employees to learn how to use it from anywhere with an internet connection – even from home!”

3 min read

Shanghai, People’s Republic of China, March 18, 2021 Simulation and optimization solutions now available at ZIMMY, China Digital engineering...

Kadkraft Systems, with over 3 decades of experience in distributing CAD/CAM, gearbox, and manufacturing simulation solutions in India, is now joining...

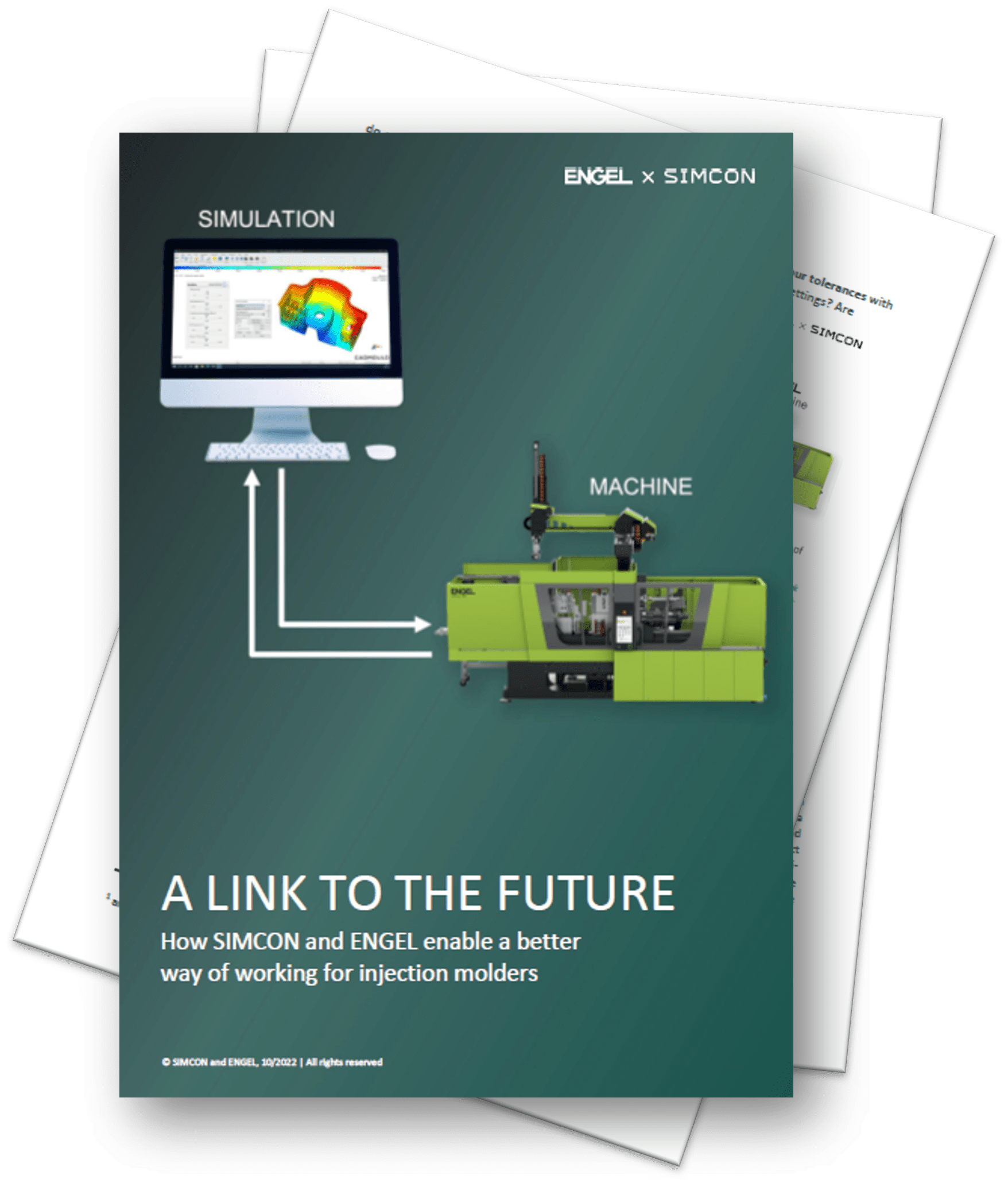

Bi-directional communication between the simulation and the machine makes it easier for engineering and the shop floor to collaborate effectively.