More than one...

CADMOULD 2K & Insert enables you to simulate two-component and multi-component parts, as well as inserts.

You can simulate parts that are produced by sequentially injecting different thermoplastics against each other.

You can also work with with inserts made of different materials (such as metal).

If these are techniques you use, then 2K & Insert represents an ideal addition to the modules Fill (simulation of filling), Pack (simulation of packing pressure and cooling phase) and Warp (simulation of shrinkage and warpage).

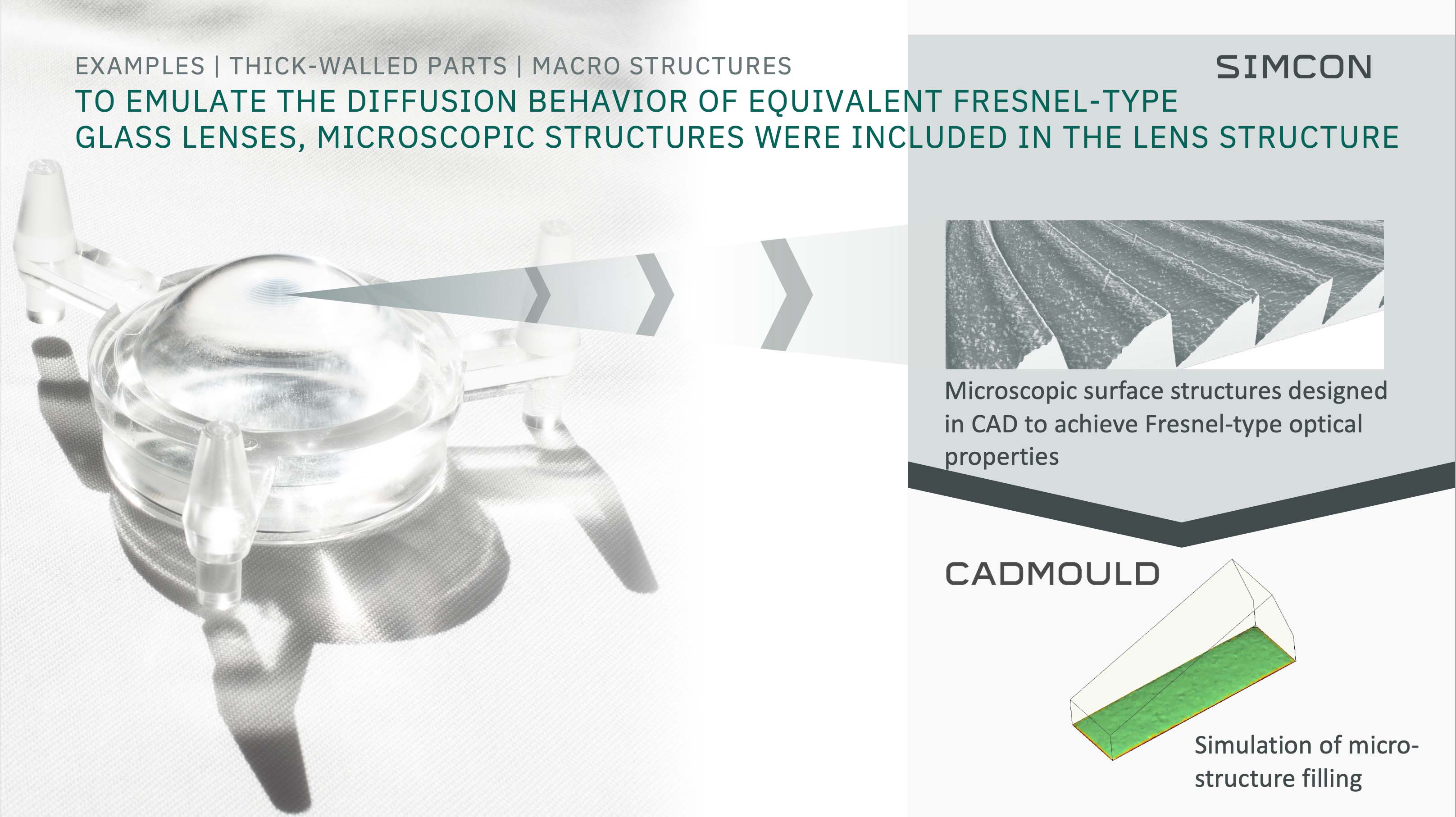

3K Optical lens with Fresnel microstructures

This part was a project we did with a few partners – Fraunhofer, KraussMaffei and Hella.

The goal of this project was to develop plastic injection molded car headlight lenses, because that is cheaper and lighter than classical glass lenses. This is possible now, because LED lights do not get as hot as classical xenon headlight bulbs.

The challenge with plastic lenses is that it is not easy to create the right optical properties, hence the part had a micro-fresnel structure at the boundary between the different components (also simulated via CADMOULD)

The research was supported by the German Federal Ministry for Education and Research. You can read more about the project here:

BMBF Page on Optisys

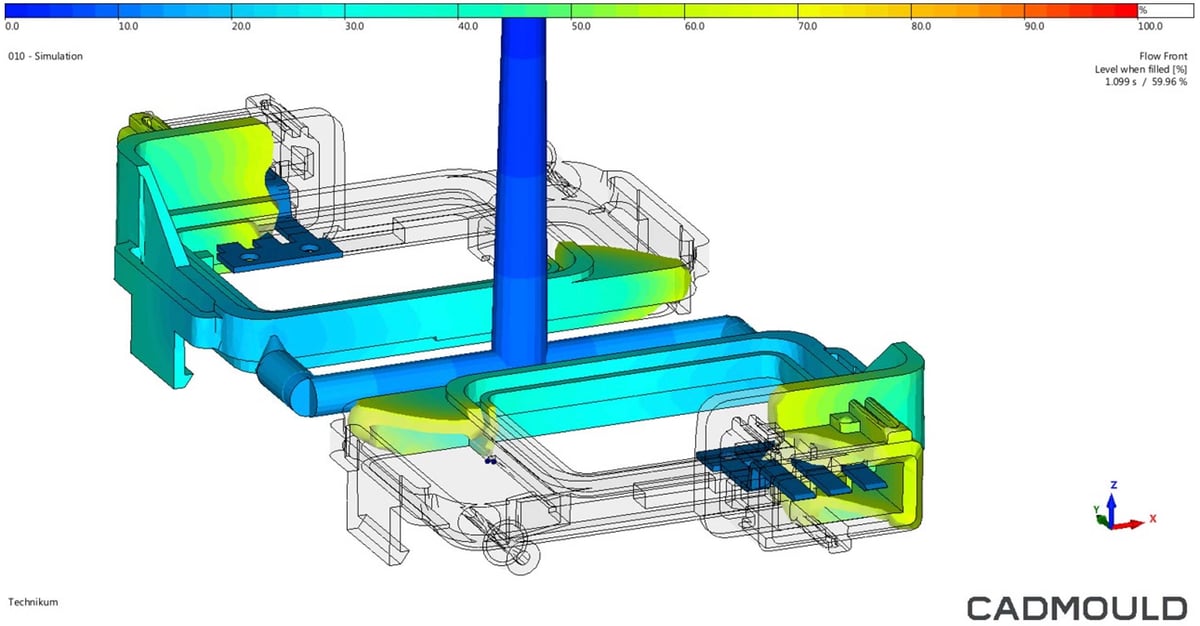

CADMOULD 2K & Insert: Filling of a multi-cavity mold with metallic inserts

Results

CADMOULD 2K & Insert computes the following results:

- Filling of the part (with multiple materials / with inserts)

- Pressure distribution

- Temperatures (also inside the components)

- Flow speeds

- Deformation of inserts or core shift during the injection phase (in combination with the Structural FEM module)

- Weld lines and air inclusions

- Freezing, sealing and demolding time

- Shrinkage, for 2K or insert parts

- Warpage

- Deformation

- Mechanical stress (including frozen residual stresses)

[1] For more details, please refer to the Structural FEM module description.

Deformation of inserts

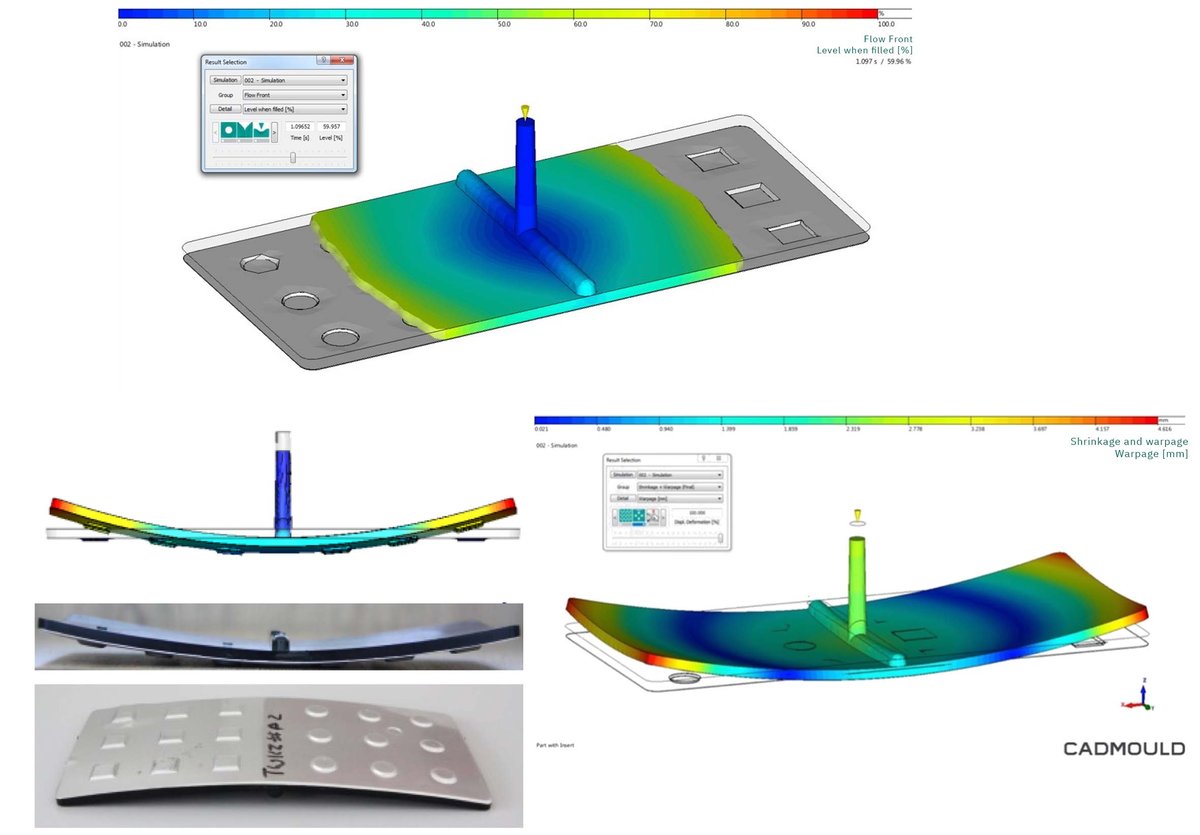

In combination with the structural FEM module, CADMOULD 2K & Insert can anticipate the deformation of inserts during the filling process.

Benefits

enables you to simulate two-component and multi-component plastic injection molding, as well as inserts.

- Optimally design 2K or multi-component processes

- Determine and optimize the thermal and mechanical influence of individual components on the part

- Detect and eliminate filling problems in multi-component parts (air inclusions, weld lines, etc.)

- Solve shrinkage and warpage issues in multi-component parts

- Identify ways to reduce the total warpage of multi-component parts

- Specify cycle times and optimal preheating temperatures of inserts

- Reduce sampling and waste, since the process parameters are already known and optimized

- As a result, get a better first-time right rate and reduce costly mold corrections. This results in significant time and cost savings

- The simulation results enable you to discuss options, advantages and disadvantages with your customers and colleagues

CADMOULD 2K & Insert: In this example, a metallic back panel is overmolded with a thermoplastic polymer. The shrinkage and warpage simulation takes into account the behavior of both the thermoplast and the metallic component.

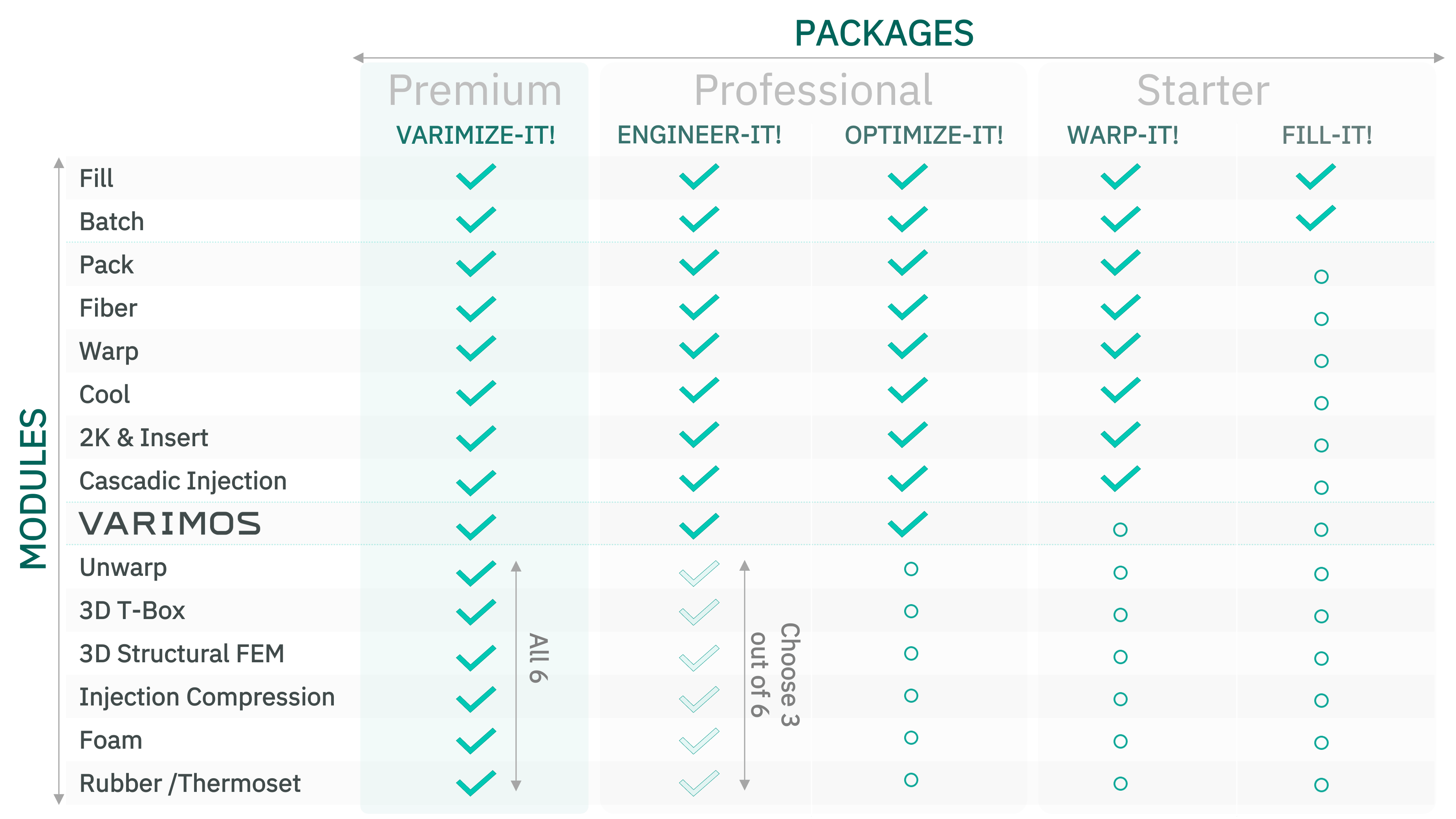

Packages and other software modules...

CADMOULD 2K & Insert is part of packages Warp-it! and above. If you have a smaller package, you can also purchase or rent the module individually.

Combine 2K & Insert with the structural FEM module to compute insert deformation.