Work with multiple gates

CADMOULD Cascadic Injection enables you to simulate cascade injection molding. It computes the same key results as the core CADMOULD modules, but with the capability of simulating sequential filling across multiple gates.

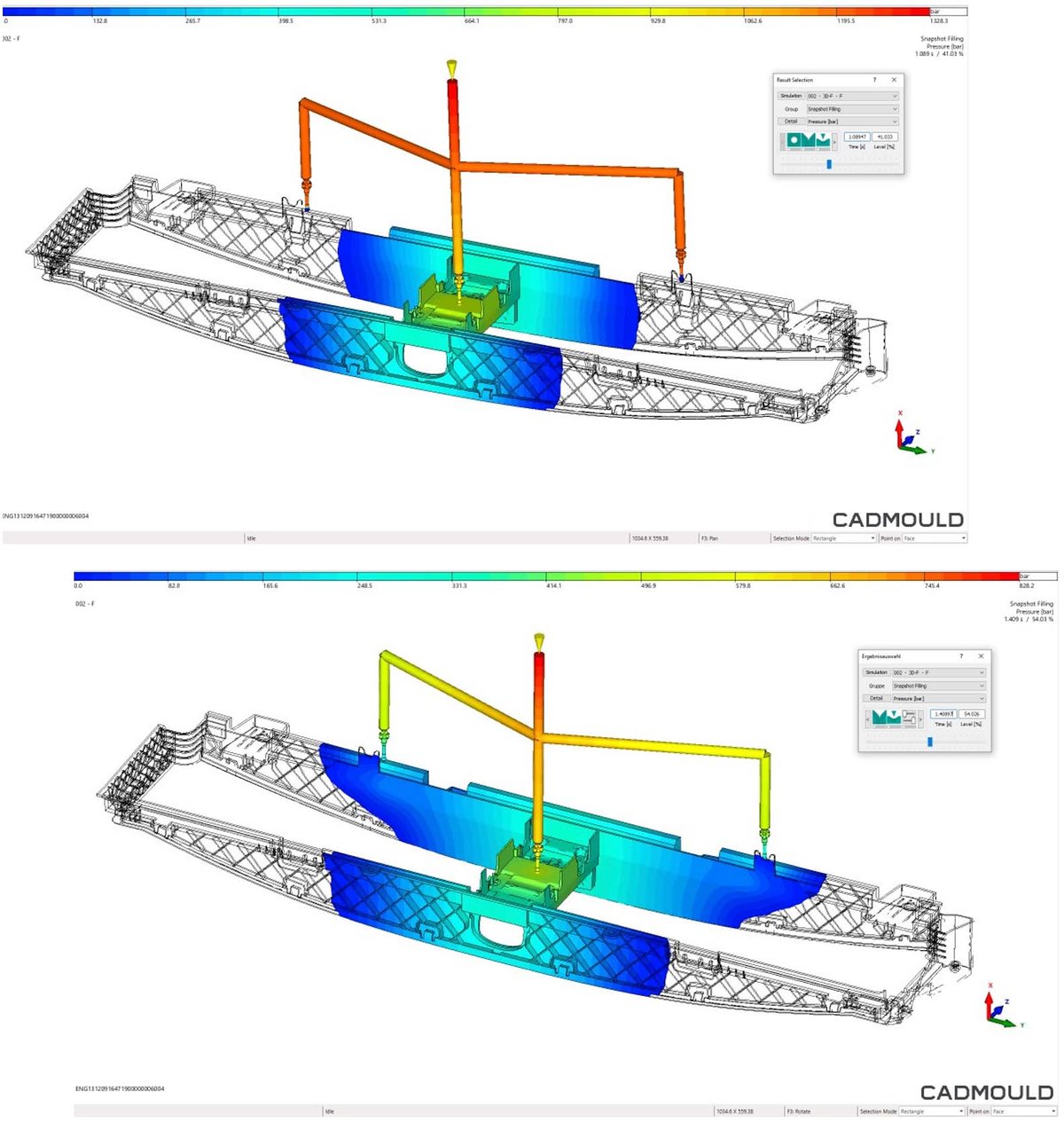

CADMOULD Cascadic Injection: Filling of a complex part with multiple gates that open in a timed sequence

Results

CADMOULD Cascadic Injection computes the following results, for cases in which multiple gates are opened sequentially

- Filling (including weld lines and air enclosures)

- Pressure distribution

- Temperatures

- Flow speeds

- Clamping forces

To generate these sequential injection molding results, Cascadic Injection module extends the functionality of modules Fill (filling simulation) and Pack (needed for packing pressure and cooling phase simulation).

Benefits

CADMOULD Cascadic Injection enables you to design the sequential opening of gates.

- Optimal design of component filling by cascade injection molding

- Determine optimal cascade timing and gate switching criteria

- Determine the maximum injection pressure and identify ways to reduce this pressure by modifying the gate control schedule

- Compute packing and cooling phase results, as influenced by the gate control. Anticipate shrinkage and warpage (requires modules Cool and Pack)

- Anticipate and fix filling problems such as air inclusions, weld lines, etc.

- Rapidly and easily compare alternative gate control schedules. Discuss advantages and disadvantages with your customers

- Optimize process parameters for existing parts and molds, to reduce the maximum injection pressure, to optimize weld line positions, and to minimize warpage

CADMOULD Cascadic Injection: Filling behavior progressing across time in a CADMOULD Cascadic injection simulation. In the top picture, only the central gate is open. A bit later (lower picture), gates 2 and 3 have opened, after the melt front has passed their locations.

Harold will explain...

Curios about how you can use CADMOULD Cascadic Injection molding simulation to better design your sequential injection molding projects?

Check out this free webinar by our veteran application engineer Harold Kutschera. He's been doing his stuff for >30 years.