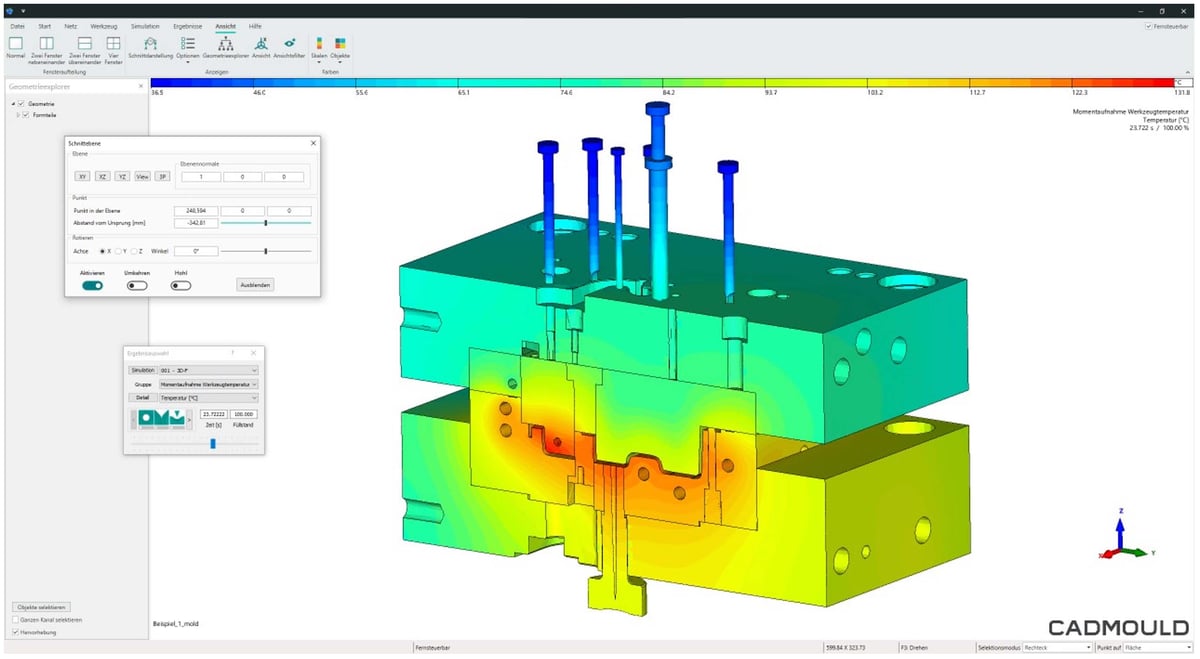

CADMOULD T-Box: evolution of temperature, along a cut through mold and part

In CADMOULD T-Box, the temperature control channels of the Cool module are combined with a complete modeling of the heat transfer processes across the entire injection mold.

T-Box offers you two options:

- You can use it early on in development, before you have a detailed CAD mold design. In this case, CADMOULD will automatically generate a generic mold sketch, consisting of temperature control, gating system and part.

- Once you have designed your mold in CAD, you can simply import it, using the CAD Importer, and use it for simulation in T-Box. This way, you can refine your temperature simulation using your fully-fleshed design.

CADMOULD T-Box: Temperature distribution along a cut through mold and part, at a specific time

Results

CADMOULD T-Box computes the following results in three-dimensional detail:

- Number of cycles to the thermally stable state of the mold

- Local variation of cavity wall temperatures during the entire cycle

- Flow rate and pressure loss in the temperature control system

- Temperature change of the tempering medium

- Turbulence of the flow

- Temperature control efficiency

Benefits

CADMOULD T-Box enables you to better account for the thermal behavior of the mold, when you design parts and molds.

- Determine cooling behavior for optimal cavity wall temperatures

- Determine cooling time

- Predict temperatures and heat flows in the mold

- Detect and eliminate hot spots due to use of different materials, mold separation or hot runner influence

- Reduce warpage through optimized mold inserts

- Reduce cycle time through mold inserts adapted to the part and the process

- Optimize existing cooling systems

- Design molds with confidence, with a better first-time right rate and fewer costly correction loops. Significant time and cost savings, and better discussions.

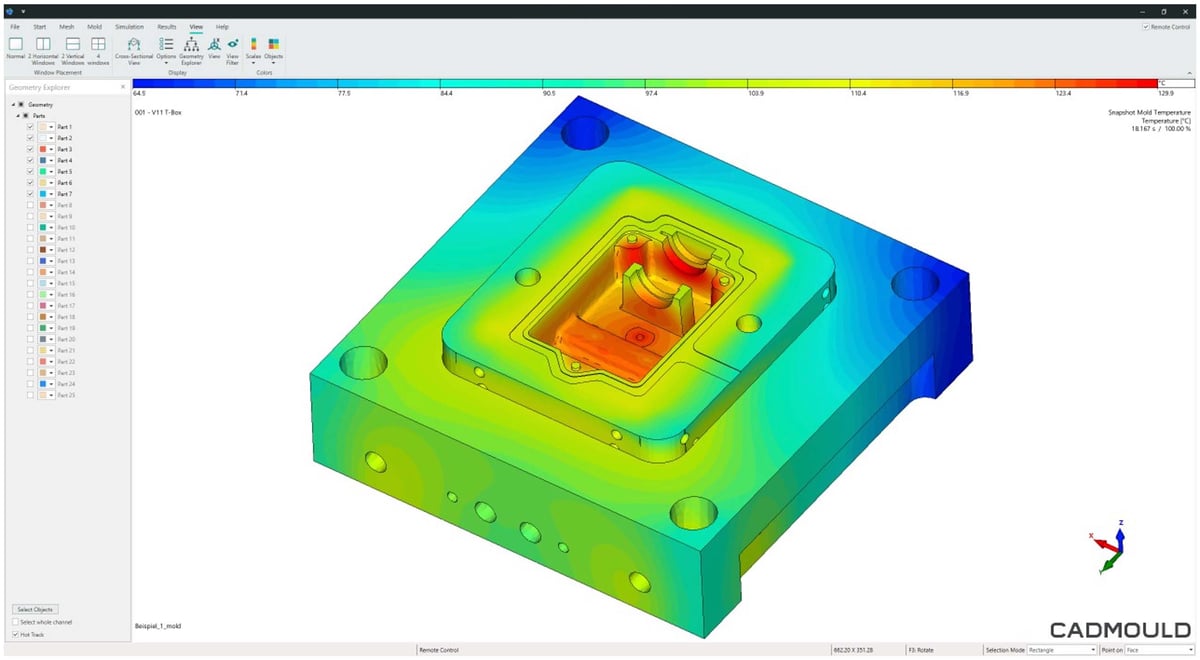

CADMOULD T-Box: Snapshot of the mold surface temperature. In this example, the cavity is shown from above.

This animation shows the evolution of the temperature across time:

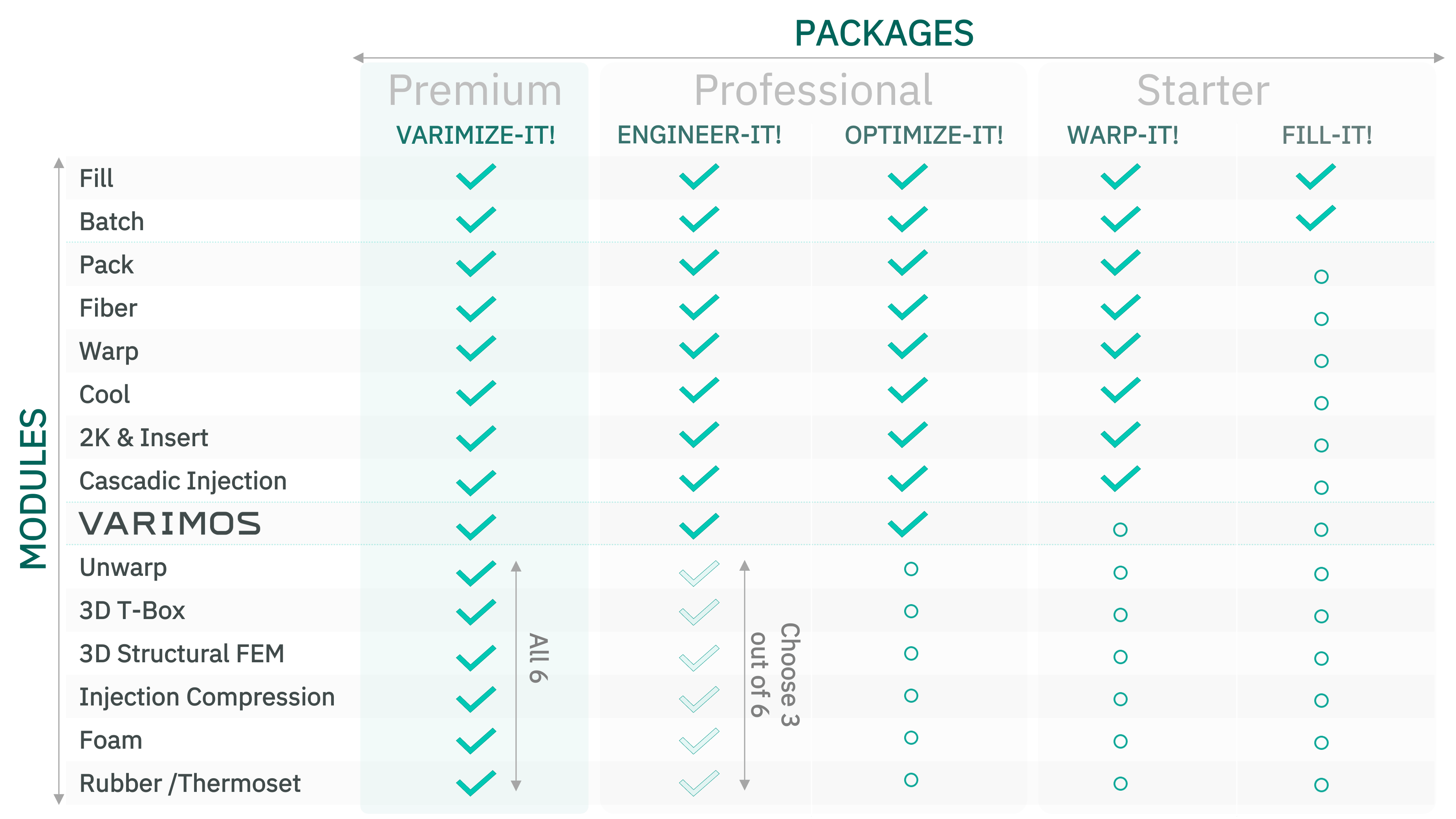

Packages and modules

CADMOULD T-Box builds on top of the functionality of the Cool module, and extends it to encompass the thermal simulation of the entire mold.

T-Box can be purchased individually, or as a part of the ENGINEER-IT! or VARIMIZE-IT! packages.