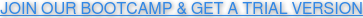

Plastic injection molding with foaming materials

By using foaming technology, you can reduce material use and create lighter-weight parts, while retaining excellent mechanical qualities. This is increasingly important to satisfy sustainability targets in sectors such as automotive and aerospace, in order to improve energy use, carbon footprint.

CADMOULD Foam enables the simulation of foam injection molding. You can simulate all common chemical and physical foam injection molding processes, such as MuCell®, Cellmould® and Optifoam®.

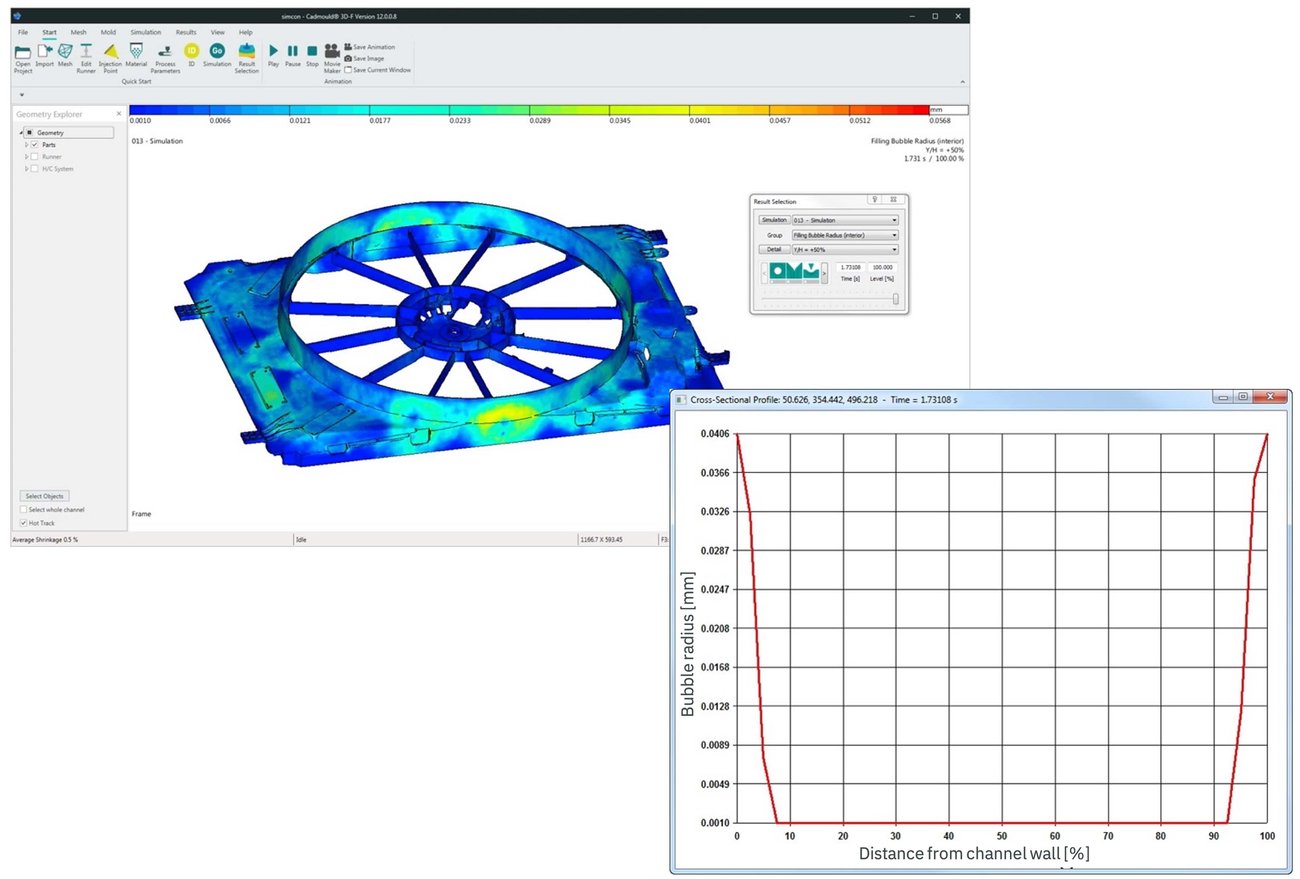

By exploring the distribution and size of bubbles across your part, you gain valuable insights into the resulting weight, mechanical behavior, and the surface quality of the part.

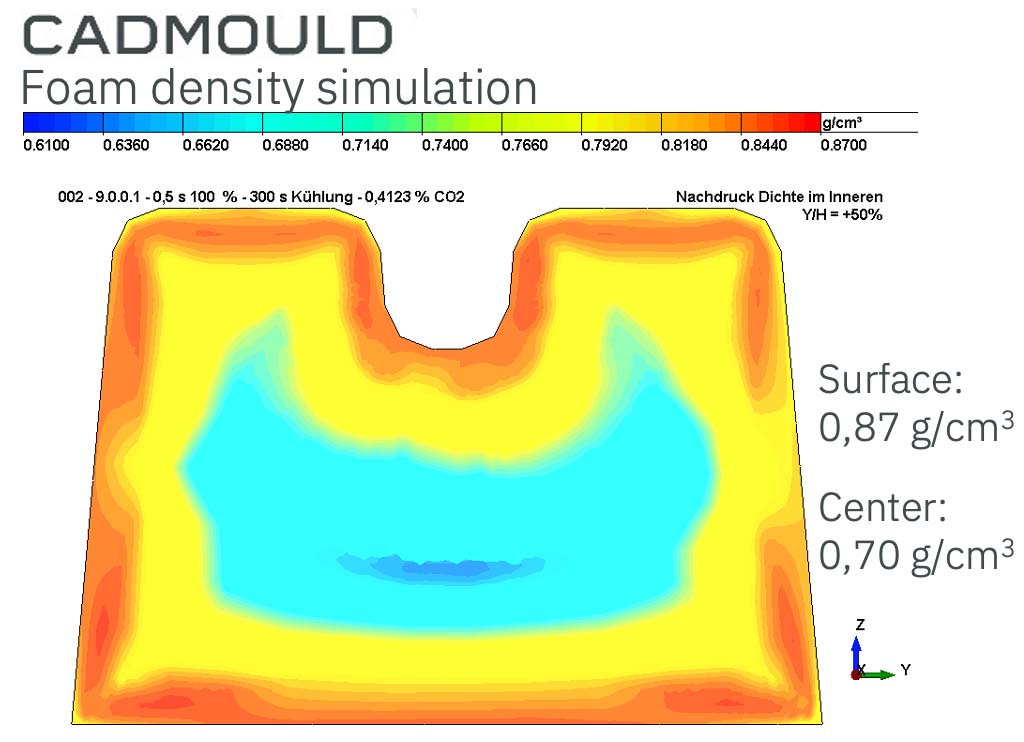

CADMOULD Foam results: Density [g /cubic cm]

Results

CADMOULD Foam computes the following results, for foam materials:

- Filling

- Density distribution in the part

- Bubble distribution and size

- Clamping forces

- Component weight

- Cooling times

- Weld lines and air inclusions

- Pressure distribution

- Temperatures

- Flow speeds

- Shrinkage and warpage

Benefits

CADMOULD Foam helps you to master your plastic injection molding projects that work with foaming materials.- Detect filling problems early on (air inclusions, weld lines, etc.), taking into account the influence of the foam on the viscosity

- Optimize propellant and gas / mass ratio

- Optimize part weight and density distribution

- Anticipate and fix shrinkage and warpage issues for foam projects

- Determine cycle times and clamping forces for foam projects

CADMOULD Foam results: bubble density viewed along a cross-section of the part