CADMOULD Structural FEM enables the simulation of a part’s mechanical behavior, taking into account fiber-related anisotropies.

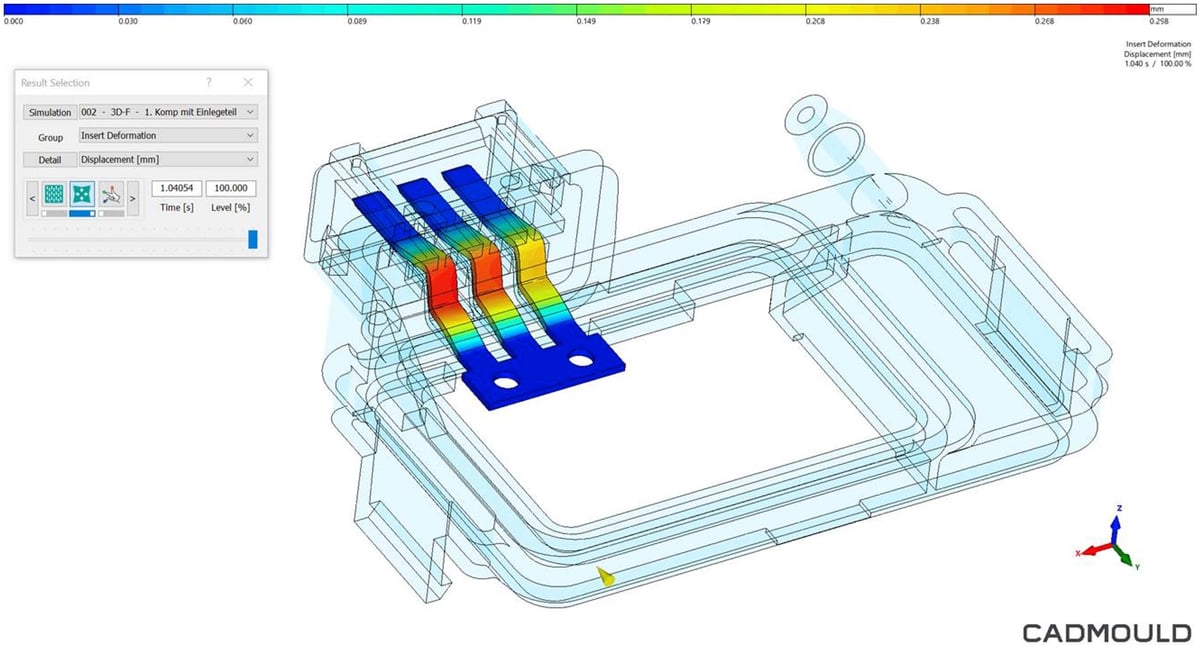

In combination with the module 2K & Insert, the deformation of inserts or the core offset during the injection phase can be simulated.

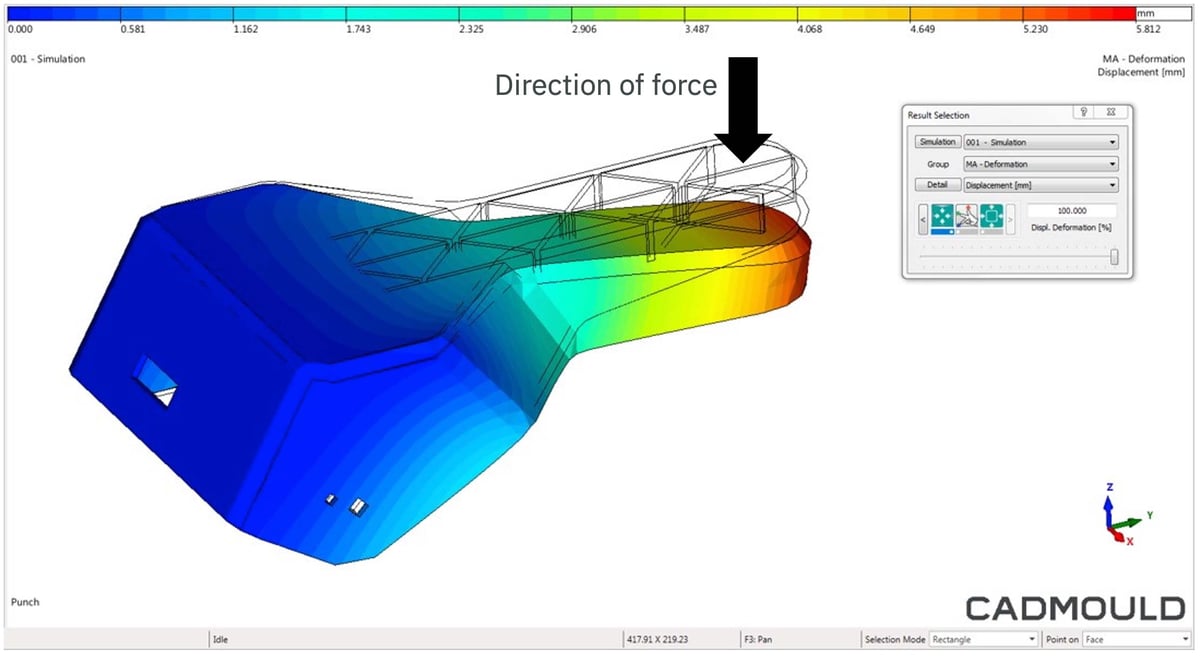

CADMOULD Structural FEM results display: MA - Deformation, displacement in mm. In this example, a force is applied to the part from above, deforming the part.

Benefits

enables you to simulate the mechanical deformation of your plastic injection molded part

- Improve engineering results by anticipating mechanical component properties

- Select materials that are compatible with expected stress and load

- Analyze the influence of fiber orientation, wall thickness and ribs on the mechanical properties of the part

- Analyze part stability and loads, once the part is built into a combined product

- Reduce mechanical stress on inserts, through optimized injection phase

- In combination with 2K & Insert: takes new thicknesses due to insert deformation or core shift into account for the filling behavior

CADMOULD Structural FEM: results display for insert deformation. The red zones are most significantly deformed relative to their intended position, during the filling of the part.

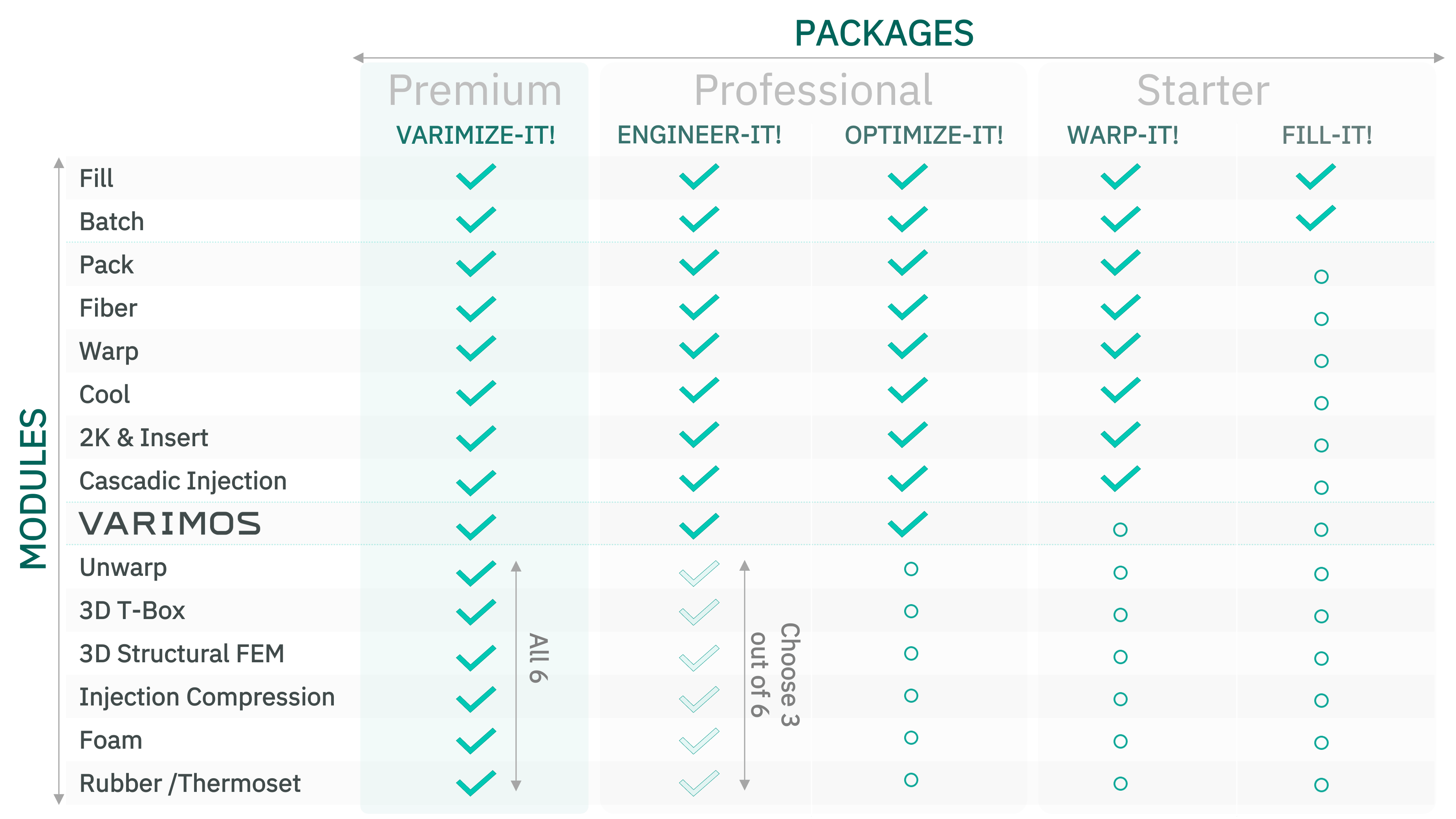

Packages and modules

CADMOULD Structural FEM can either be purchased as an individual module, or as a part of the Engineer-it! or Varimize-it! packages.

The Structural FEM module is thus an ideal complement to the Fill (simulation of the filling), Pack (simulation of the holding pressure and cooling phase) and Fiber (simulation of fiber orientation) modules.

In combination with the module 2K & Insert, the deformation of inserts or the core offset during the injection phase can be simulated.