Advantages and disadvantages of injection molding simulation

Find out what the advantages and disadvantages of plastic injection molding simulation are. Our opinion: if the prerequisites are right, it only...

1 min read

.jpg) SIMCON and HellermannTyton

04.10.2021

SIMCON and HellermannTyton

04.10.2021

It’s good to be good, but it’s better to be better

In times of ever-accelerating changes in market conditions, shorter product cycles, intensifying global competition in high-end manufacturing and rapid technological change, it is worth looking at your ways of working and asking: how can we do better?

HellermannTyton and SIMCON have now published a joint article outlining their views on the success factors for a modern simultaneous engineering process for plastic injection molding.

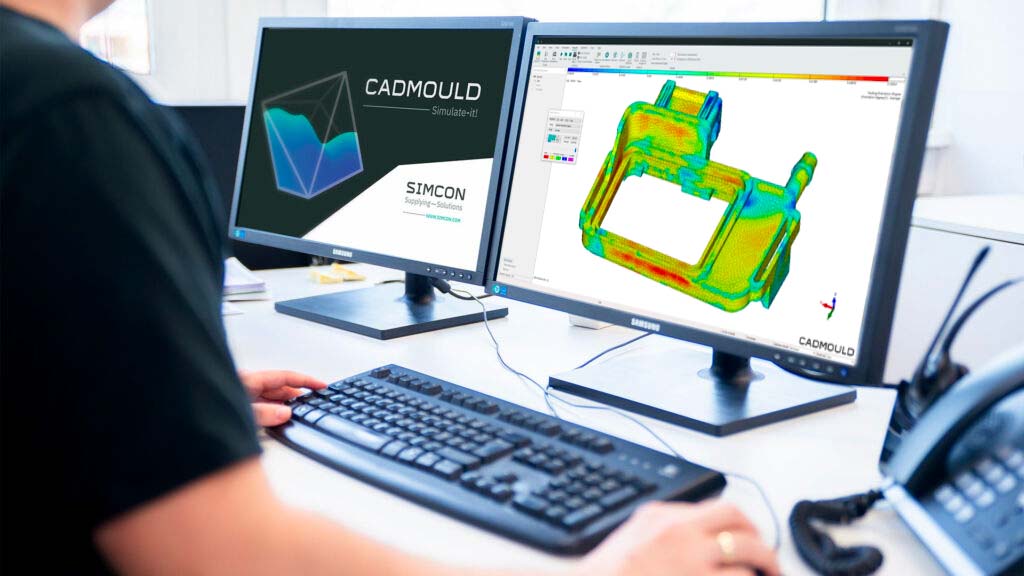

Design virtualization plays a major role in this context. By simulating the injection molding process, it is possible to create a digital twin that is ideal for interdisciplinary collaboration.

Virtualization enables part designers, mold designers and machine setters to identify and solve the problems of a design in a front-loaded way, before the mold has been built. Changing and updating a digital design is considerably cheaper and faster than modifying and correcting a physical mold made of steel.

As a result, issues are caught and fixed early, during virtual design. Meaningful changes and improvements can be implemented before incurring the cost and commitment of building the mold. Mold corrections are reduced, saving costs and improving time-to-market.

Read our joint article to see an example!

In the article, this approach is illustrated by an electric charging socket holder for a prestigious sports-car OEM. If you are seeking inspiration for redesigning your own ways of working, you can download the article here:

Find out what the advantages and disadvantages of plastic injection molding simulation are. Our opinion: if the prerequisites are right, it only...

Better first-time-right through a better way of working Our whitepaper “HOW (NOT) TO DIGITALIZE YOUR PLASTIC INJECTION MOLDING DESIGN PROCESS”...

3 min read

Shanghai, People’s Republic of China, March 18, 2021 Simulation and optimization solutions now available at ZIMMY, China Digital engineering...