1 min read

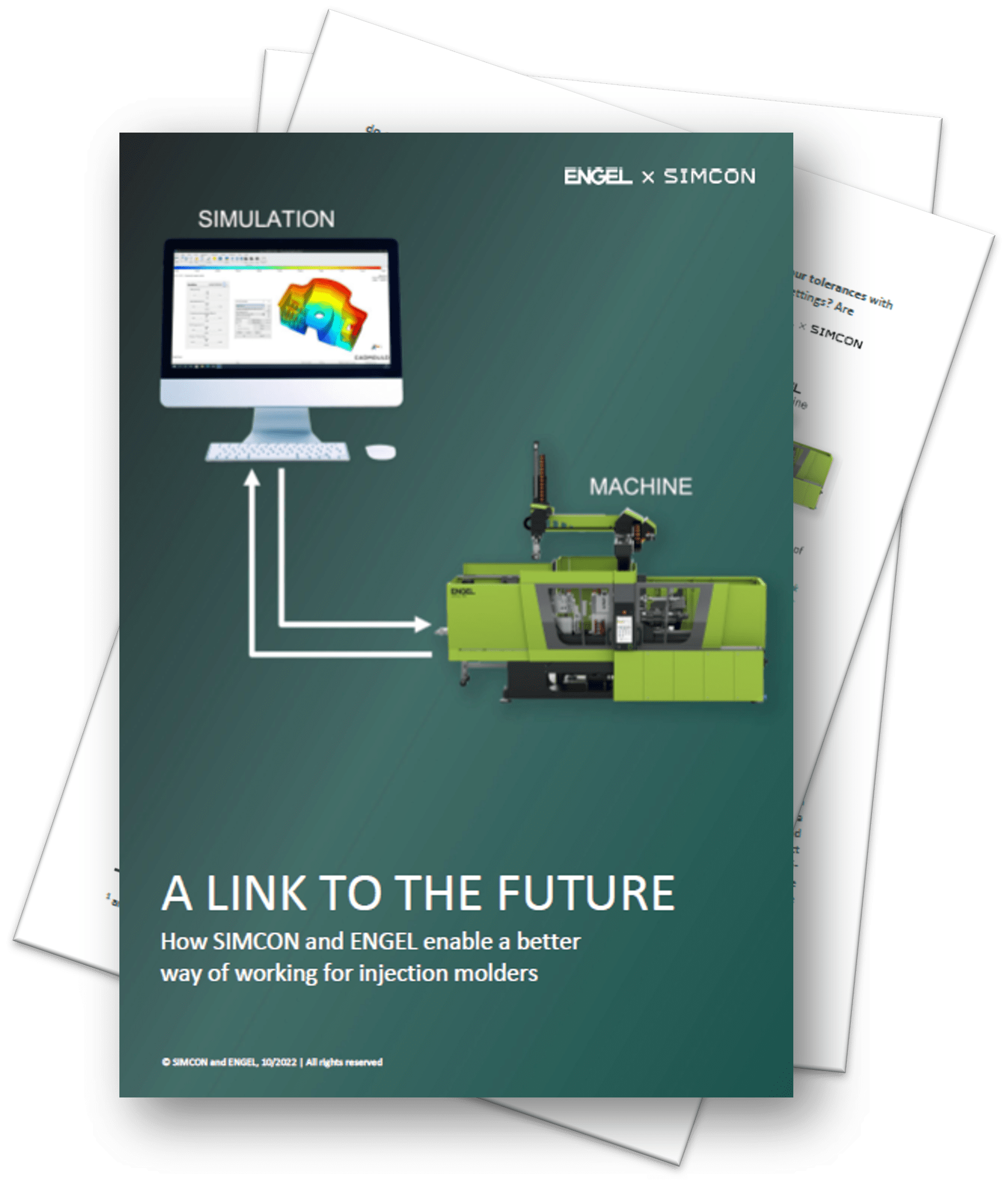

Link to the future: How ENGEL & SIMCON enable a better way of working

Bi-directional communication between the simulation and the machine makes it easier for engineering and the shop floor to collaborate effectively.

Read More

1 min read

Bi-directional communication between the simulation and the machine makes it easier for engineering and the shop floor to collaborate effectively.

Read More

1 min read

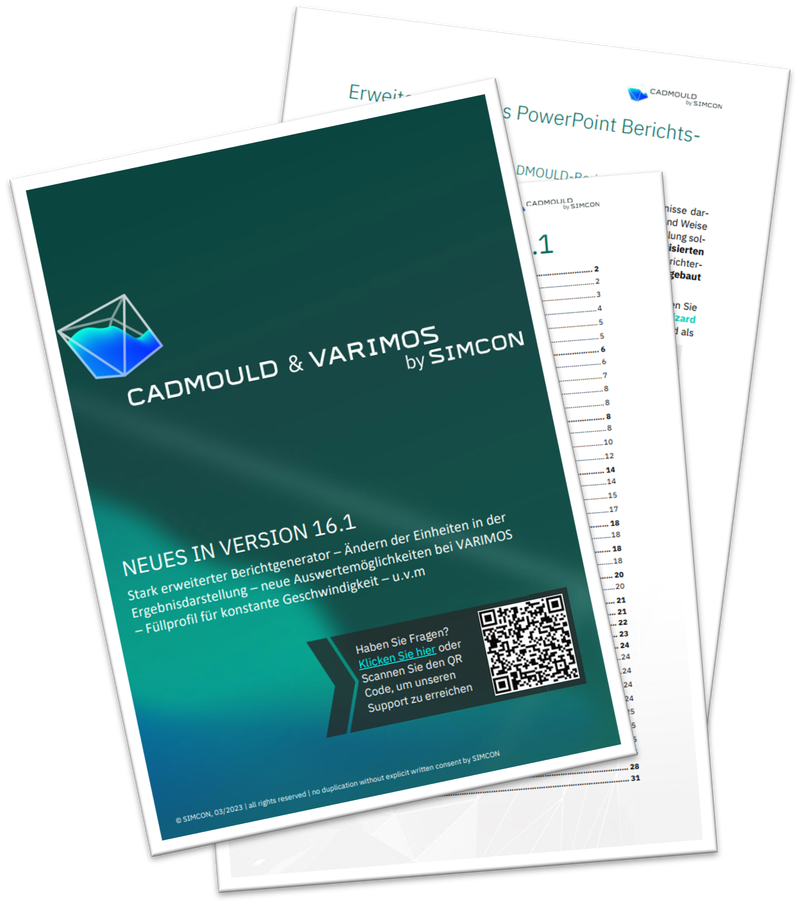

Paperless parameter transfer from simulation to the injection molding machine is crucial, if injection molders want better results.

1 min read

Fast series production with significantly reduced warpage. This was the result of PLASTON and GOLLMER Formen working together to refine the mold...

3 min read

Kadkraft Systems, with over 3 decades of experience in distributing CAD/CAM, gearbox, and manufacturing simulation solutions in India, is now joining...

2 min read

Find out what the advantages and disadvantages of plastic injection molding simulation are. Our opinion: if the prerequisites are right, it only...

1 min read

You are looking for a new plastic injection molding simulation software and not quite sure where or how to start your search and what exactly is...

2 min read

2020 has been a challenging environment for many companies, on many fronts. Due to the pandemic, the macroeconomic climate has been challenging....

3 min read

Koorean CAD/CAM specialist INCOS INC is now distributing SIMCON’s plastic injection molding simulation and optimization software CADMOULD and VARIMOS.

2 min read

1. Use The Right Material And Not Too Much Of It! Which material you choose has a significant impact on your costs. The material you initially select...

3 min read

Shanghai, People’s Republic of China, March 18, 2021 Simulation and optimization solutions now available at ZIMMY, China Digital engineering...