Anticipate

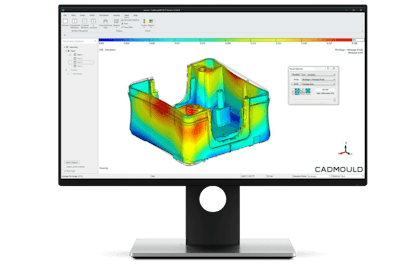

Predict what will happen inside the mold, before you build the mold. Identify issues before they happen! Understand why issues occur.

Achieve higher quality plastic injection molding results, faster.

We're passionate about plastic injection molding. We've been helping our customers with their most demanding engineering challenges for more than 30 years. We developed CADMOULD and VARIMOS to be able to answer our customers' toughest questions. Virtualize your engineering and get better results!

With our powerful virtualization tools, you can anticipate and avoid errors, and achieve better results, faster. As a result, you get reduced cost of corrections, faster time to market, and better serial production (better quality, faster cycle times, less material waste, etc.)

Predict what will happen inside the mold, before you build the mold. Identify issues before they happen! Understand why issues occur.

Test different solutions before you build the mold. Check what works. Virtualize your mold corrections! Get it right the first time!

Find superior solutions. Improve cycle times. Reduce cost. Reduce material and energy use. Improve sustainability.

Achieve better results faster than with trial and error. Less time on mold corrections. Shorter time to market! Test many solutions at once, in parallel and learn faster.

Hint: digital transformation is more than "just" installing a piece of software. It's about a distinctive upgrade in the way you work on a daily basis! It's about teamwork and better communication as much as it is about software.

Read our whitepaper (co-authored with Volume Graphics) on how to modernize your digital injection molding design ways of working!

Avoid typical pitfalls and upgrade the way you work today!

Satisfied customers

Years of experience

Projects served

by Dr. Bastiaan Oud & Dr. Paul Filz (SIMCON) with Johannes Mann & Kai Winter (Volume Graphics)

by SIMCON and HellermannTyton